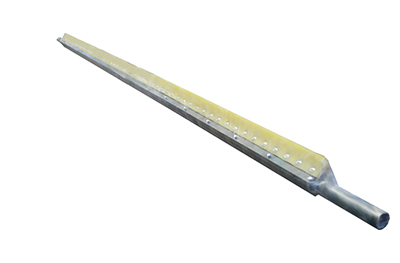

The patented BaroMat sets standards. After a very detailed and thorough practical testing at conveyor belts in various industrial sectors, the BaroMat is a proven technology with utmost efficiency for many years. The basis of the patented, belt friendly system is a steal beam with an integrated elastic scraping element, which is constantly pressed against the conveyor belt with low air pressure across the entire belt width. The whole scraping element is adapted individually to the surface of the drum and the belt. This enables a constantly good and complete cleaning of the conveyor belt. Even if the drums are effected crowned, the scraper adapts to the shape of the drum. In consequence the belt wear is effectively compensated.

Thereby, the BaroMat operates more effectively and economically than conventional scraping systems. The comparatively low acquisition costs face a high cleansing effect. The low space requirement is a further advantage of the BaroMat.

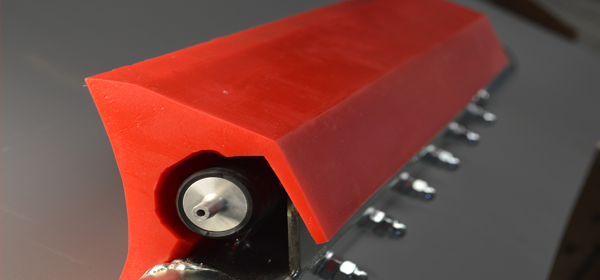

An elastic pressure tube in between bearing structure and scraper element provides the necessary pressing pressure regarding to the conveyor belt. A pressure regulator makes sure that the pressure within the system is stable and remains constant. The Baromat gets the necessary compressed air from the available operational air pressure supply. If there is no central pressure air supply a corresponding pressure storage can be supplied. There is no air consumption with the Baromat.

The BaroMat is especially suitable for reversing operation. A particular advantage is that the not needed scraper will be removed from conveyor belt by a special reversing valve which is connected with the electrical control of the conveyor belt.

Pressure regulator in protective housing for reversing mode

The Baromat works nearly maintenance-free. The scraping element consists of a single part and can easily be exchanged. Due to the simple handling, downtimes remain minimal.